Plasma Asher

Updated 9 November 2023

Introduction

Small inorganic samples are sometimes associated with detrital organic matter which needs to be removed before analysis. Oxygen plasma ashing is a room temperature method for doing this removal without further contamination. It is essentially slow, and therefore cold, combustion without the usual pyrolysis, charring and flames.

Publication

A small radio frequency plasma asher, based on earlier work ( Oxygen Plasma Asher. J E Patterson. Analytical Chemistry, 51, 1978, 1087-1089), has been constructed. The glassware design originally used standard parts joined by short lengths of Tygon plastic tubing. Samples were ashed in the discharge zone, which was not very warm.

In this current design the plasma generation and sample areas are separate so ashing takes place at room temperature. Also, air can be used instead of oxygen.

RF Power Supply

The 30 Watt Westinghouse RF power supply was originally used to run electrodeless discharge lamps for use in atomic absorption spectrometry. Any RF power supply, capable of more than 10 watts output at 27.12 MHz, should be suitable.

Design

The resonator consists of a 29 turn coil air wound with 1.7 mm diameter solid copper wire to an internal diameter of 30 mm. RF is fed in at the sample end of the coil. The coil is grounded at 4 turns and tuned with a 0-50 pF variable capacitor connected to another tap at 10 turns. The remaining turns are not terminated. They couple capacitively with the case. This design delivers a high electric field gradient suitable for starting a plasma at low power and is able to sustain it at a power level of less than 0.5 watts.

The sample tube is derived from a standard Quickfit Dreshsel bottle head mf 28/3/125. Currently the capillary is at the end of the stem and a simple Quickfit 24/3/8 test-tube can be used to hold the sample. The stem now runs almost the full length of the test-tube. The stem is deviated so more room is avaiable for samples like SEM stubs. A teflon sleeve was used in the 24/29 socket to make sample changing easier.

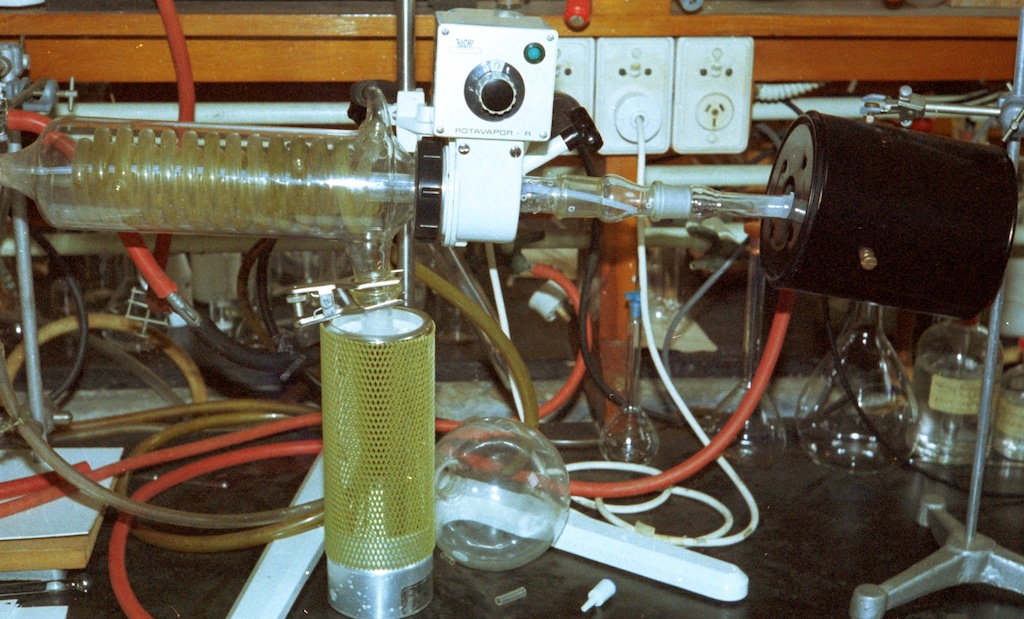

In 1984 a variation of this plasma asher was used for difficult samples like coal. It was based on an old Buchi Evaporator which used similar glass fittings. Samples could be rotated and agitated while under vacuum. Some glass balls could be added to refresh the sample surface.

Reactions

The plasma generation reactions after oxygen ionisation are:

O2 + O+ ---> O2++ O.

O2++ e----> O. + O.

The oxygen radical O. reacts directly with organic matter. Reaction products are all gases and can include CO2, CO, H2 and H2O.

Oxygen's ionisation potential is 12 eV while nitrogen's is 15.5 eV. If nitrogen, in air, is ionised then rapid reactions occur with oxygen radicals to form NO+. This reduces the oxidation rate.

At 10 watts rf power and at a vacuum of about 0.5 millibars air pressure, enough oxygen radicals survive to allow the ashing of organic matter to take place at room temperature.

Ashing

- Typical weight losses are 5mg/hour at 10 watts RF power, using a 0.5g rod of pure graphite as a sample.

- Changing to a pure oxygen carrier increases the ashing rate to to more than 10mg/hour.

- Cellulose based materials ash reasonably fast. Bulk solids ash slowly - sometimes slower than 1mg/hour.

- The ashing rate increases with sample size and the exposed surface area.

- Downstream of the oxygen plasma the ashing rate of a mylar film is about 0.4 microns per hour at 10 watts RF power. In the plasma the ashing rate of a mylar film is about 1 micron per hour. This is a useful guide for organic layer removal from natural samples such as shells.

- Oils and samples like butter, placed directly in the plasma, melt, polymerise and then ash.

- Ashing in the plasma is several times faster than ashing downstream, but the temperature is slightly higher.

- Metal and graphite samples heat up in the RF field. Ashing downstream is OK.

- Salts develop colour centres in the plasma. Sodium chloride goes blue and lithium chloride goes red.

- A high ash content inhibits further ashing. Coal, for example, needs to be powdered and requires a lot of stirring for complete ashing.

- There is a slight colour change in the plasma when ashing is complete - the spectra from H2 CO and CO2 is missing.

- Freeze drying organic samples increases the ashing rate because the accessible surface area is higher.

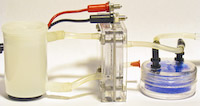

Oxygen Generator

An oxygen generator, based on a 300mA Proton Exchange Membrane (PEM) Fuel Cell, has been added. Much improved ashing rates are now possible.

The air or oxygen pressure is controlled by a fixed capillary which is adjusted once, either by partially fusing the end or by grinding the end back. There is little need to use an expensive valve for this task.

Sample Preparation

A photo above shows small sample bottles containing rare foraminifera, with the plasma asher in the background. Foraminifera often have a layer of organic material on the surface which should be removed before inorganic analysis. To remove the organic material a bottle containing the samples is opened and placed directly in the plasma asher. The ashing time required is determined beforehand by using a inkjet printed test strip. It fades as the layer of ink is removed. The printed text on a receipt is another good test object. For these samples a 1 hour ashing time was optimum. The samples were not touched.

The plasma asher can be used to prepare the surfaces of samples for electron microscopy and laser ablation ICPMS. In the case of electron microscopy the samples can be mounted on a stub before ashing. Organic films, such as resists, can be selectively removed without the application of heat, or the use of toxic chemicals. Another application is the treatment of hydrophobic plastic surfaces, before using adhesives.

Optical end-point detector

I have recently added an optical end-point detector shown at lower right. The detector is made by using an old eprom as a light detector. The photocurrent is fed into an operational amplifier configured as a basic current amplifier. The output is recorded with a Pico data logger and my Massport software.

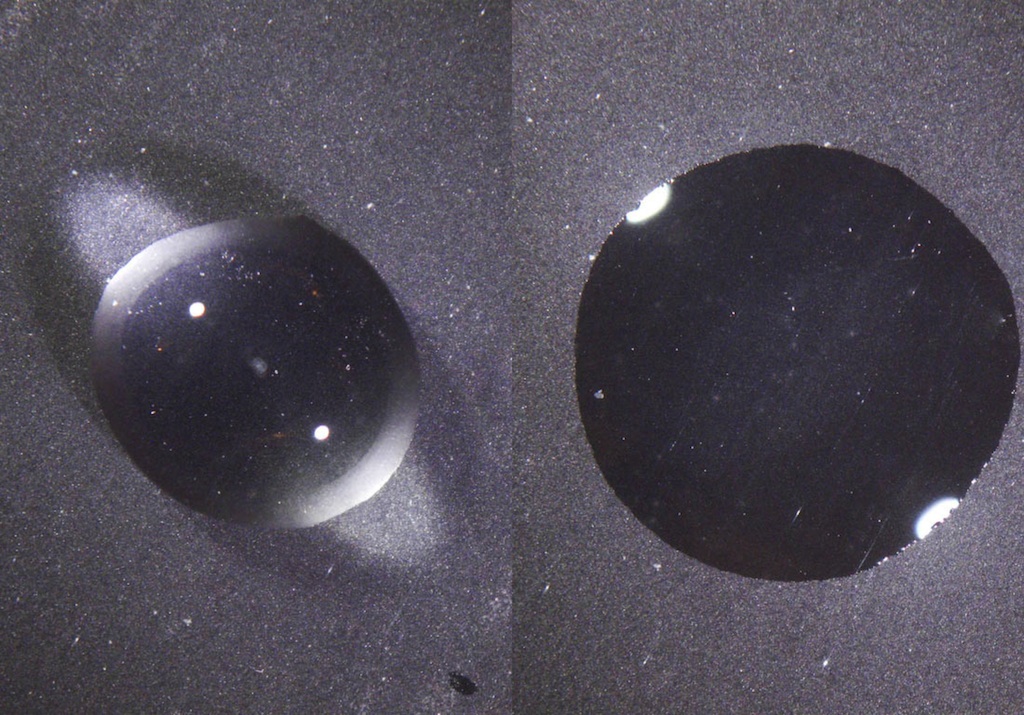

Glow Discharge

The plasma forms a glow discharge which only extends along the tube when most of the sample has been processed. Photos of the afterglow are seen below and at right The light intensity from this afterglow is measured and recorded. No filters are needed.

The ashing should end after the curve finishes sloping upwards and levels out. Some noise at the end of the run is probably caused by the increasingly fragile sample moving.

Plasma glow discharge after completed ashing of a plant sample on a SEM stub

Small commercial plasma ashers

The EMS1050X Plasma Asher is available from ProSciTech.

The SPI Plasma-Prep II Plasma Etcher, Cleaner and Asher is available from SPI Supplies.

The Theirry Corporation makes a nice range of Plasma Ashers.

JEPSPECTRO - Home Page

Email: replace at with @

jepattersonatactrix.co.nz

Transparent petals on a partially ashed flower

Transparent petals on a partially ashed flower

Plasma asher resonator

Plasma asher resonator

Dummy load for RF tuning

Dummy load for RF tuning

Fixed flow rate capillary

Fixed flow rate capillary

PEM fuel cell oxygen generator

PEM fuel cell oxygen generator

Crab leg clean up for analysis by laser ablation ICPMS

Crab leg clean up for analysis by laser ablation ICPMS

SEM stub holder for surface layer removal

SEM stub holder for surface layer removal

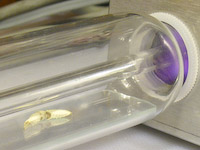

Plasma asher sample cell

Plasma asher sample cell

Plasma ashed carrot leaf

Plasma ashed carrot leaf

Optical endpoint detector and an output plot on the computer

Optical endpoint detector and an output plot on the computer